-

Search

Properties

Thermal Properties

Vectran™ HT LCP fiber has excellent thermal properties, especially in regard to thermal loading.

Fiber thermal properties

| Vectran™ | Aramid | |||

|---|---|---|---|---|

| HT | UM | Standard | High Modulus | |

| LOI | 28 | 30 | 30 | 30 |

| M.P., °C | None | 350 | None | None |

| HAS (hot-air shrink, 180°C, 30 minutes), % | < 0.2 | < 0.1 | < 0.2 | < 0.1 |

| BWS (boiling water shrinkage, 100°C, 30 minutes), % | < 0.2 | < 0.1 | < 0.2 | < 0.1 |

| 50% Strength Retention Temperature, °C | 145 | 150 | 400 | 230 |

| TGA (20% weight loss), °C | > 450 | > 450 | > 450 | > 450 |

Equilibrium moisture regain

| Temperature (°C) |

Relative Humidity (%) |

VECTRAN™ | Aramid | ||

|---|---|---|---|---|---|

| HT | UM | Standard | High Modulus | ||

| 20 | 65 | < 0.1 | < 0.1 | 4.2 | 4.1 |

| 20 | 80 | < 0.1 | < 0.1 | 4.8 | 4.8 |

| 20 | 90 | < 0.1 | < 0.1 | 5.4 | 5.5 |

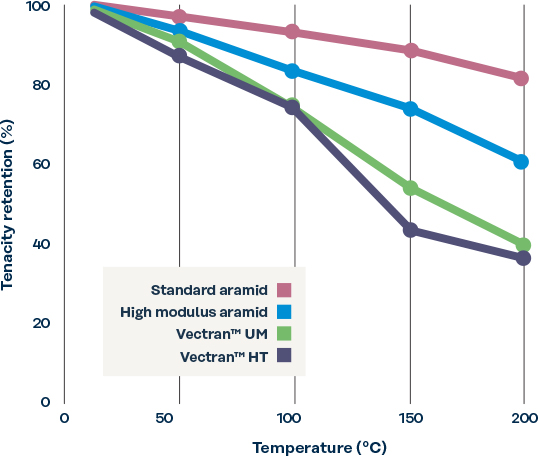

Vectran™ at high temperature

Mechanical property retention during or after thermal exposure is a key concern in many applications. The tensile strength of Vectran™ at temperature should be used as a reference in selecting process conditions.

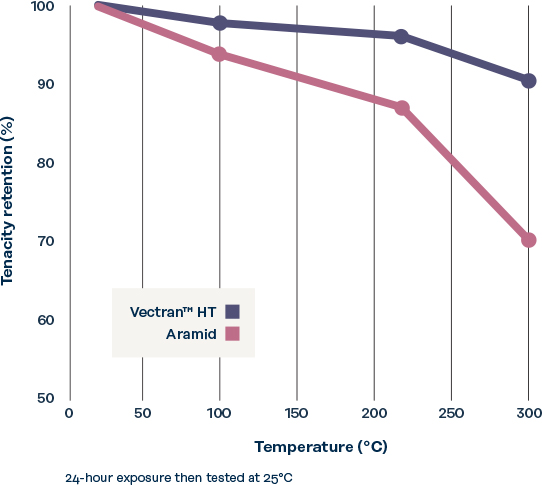

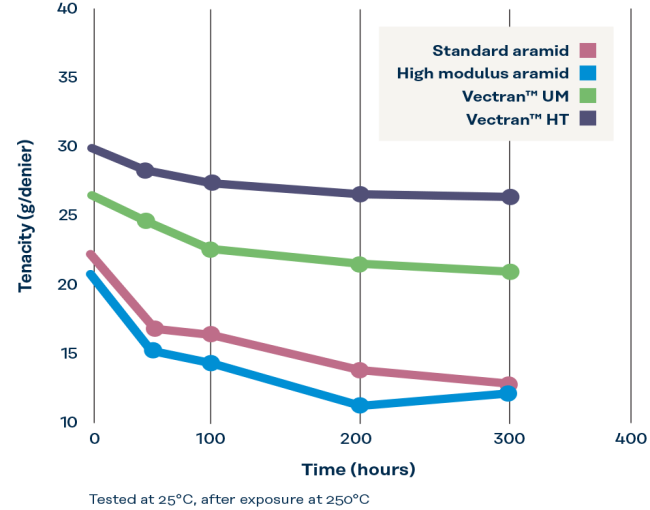

Vectran™ after thermal exposure

For high-temperature processing at low mechanical load, Vectran™ will have excellent strength after processing, superior to aramids.

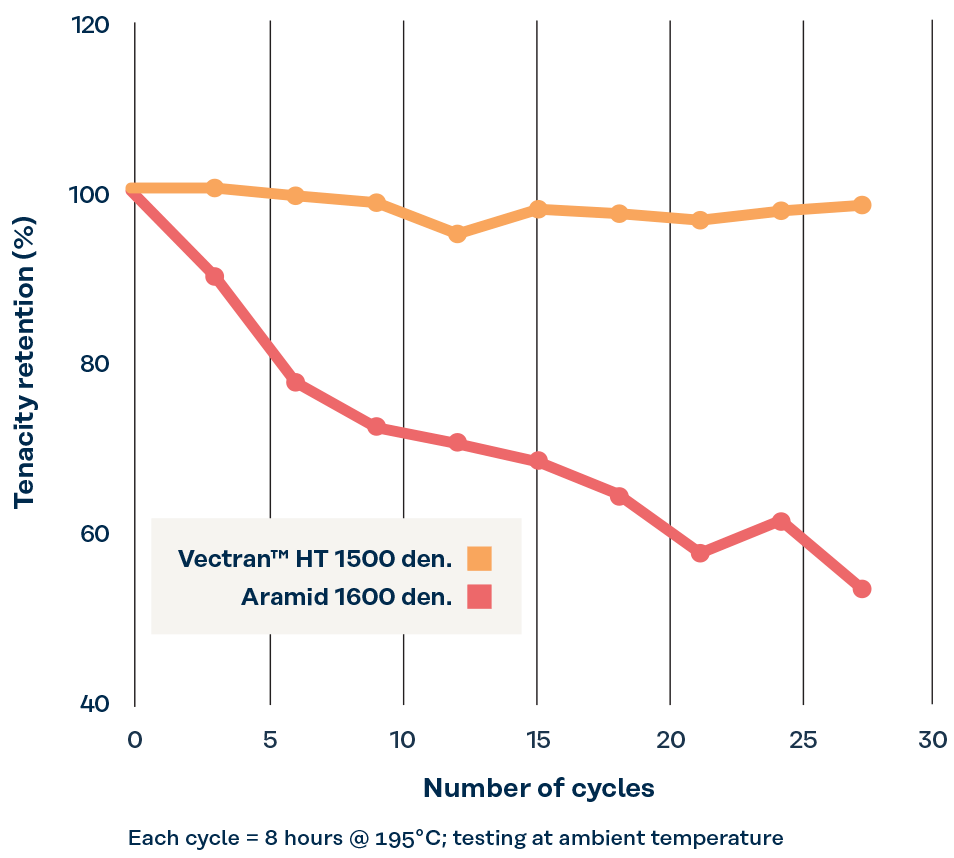

Vectran™ resistance to cyclic thermal loads

The resistance of Vectran™ to cyclic thermal loads at higher temperatures is superior to aramids and increases product lifetimes.

Resistant to thermal aging

Dry Heat

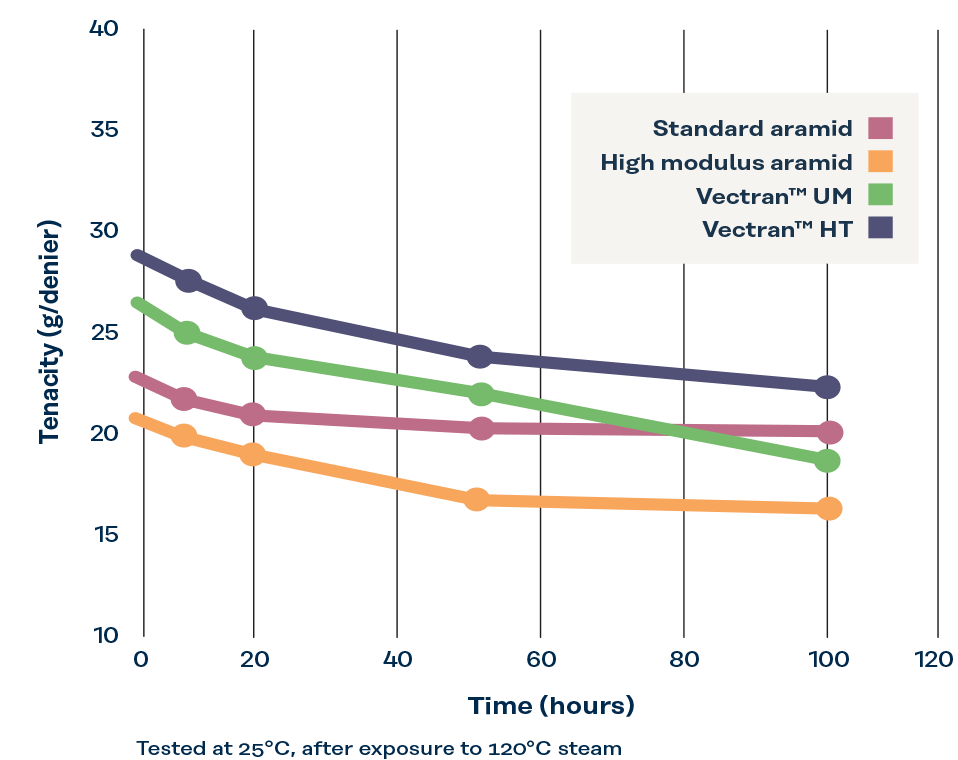

Wet Steam