-

Search

Properties

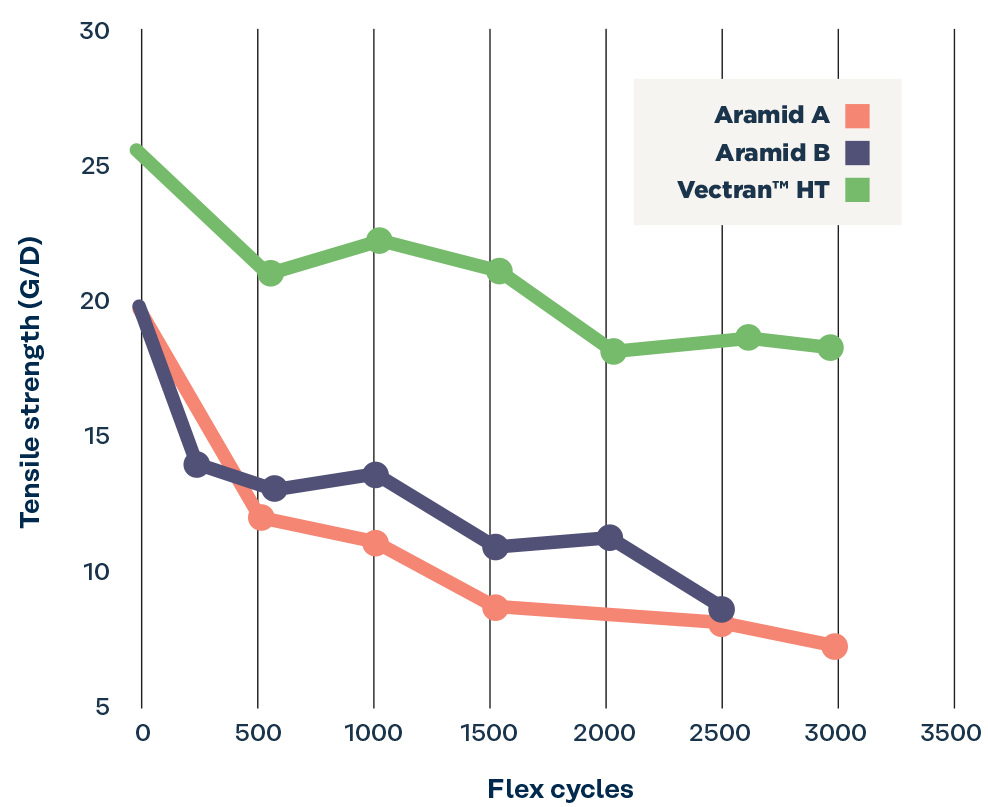

Flex Fatigue Resistance

Flexural fatigue is a critical concern in many applications where yarns or fabrics are subject to repeated bending or creasing. Examples include ropes, sailcloth, inflatable and/or temporary structures, etc. Improving the service life of products by increasing flex fatigue resistance is an important driver for the use of Vectran™ fibers.

Fatigue testing of coated fabrics

| Base material | Tenacity loss at failure location 100 cycles, % | Failure location |

|---|---|---|

| Vectran™ | 0.8 | Away from fatigued crease |

| Aramid | 22.9 | At crease |

Flex fatigue results on 1500D yarn

| Material | Cycles-to-Failure |

|---|---|

| Vectran™ T97 | 115,113 |

| Aramid 1 | 5,114 |

| Aramid 2 | 40,666 |

| Aramid 3 | 1,383 |

| PBO | 23,821 |

Test conditions: Tinius Olsen tester, ASTM D2176-97a, modified for yarn, 2 kg weight

Flex fatigue results on 2 mm cords

| Material | Cycles-to-Failure |

|---|---|

| Vectran™ T117 | 41,909 |

| Aramid 1 | 2,115 |

| Aramid 2 | 14,963 |

| Aramid 3 | 8,143 |

| PBO | 25,158 |

Construction: parallel core/extruded jacket. Test conditions: 45 mm dia pulley, 45 kg test load, 58 cycles/min, 5 tests/sample on cyclic test machine

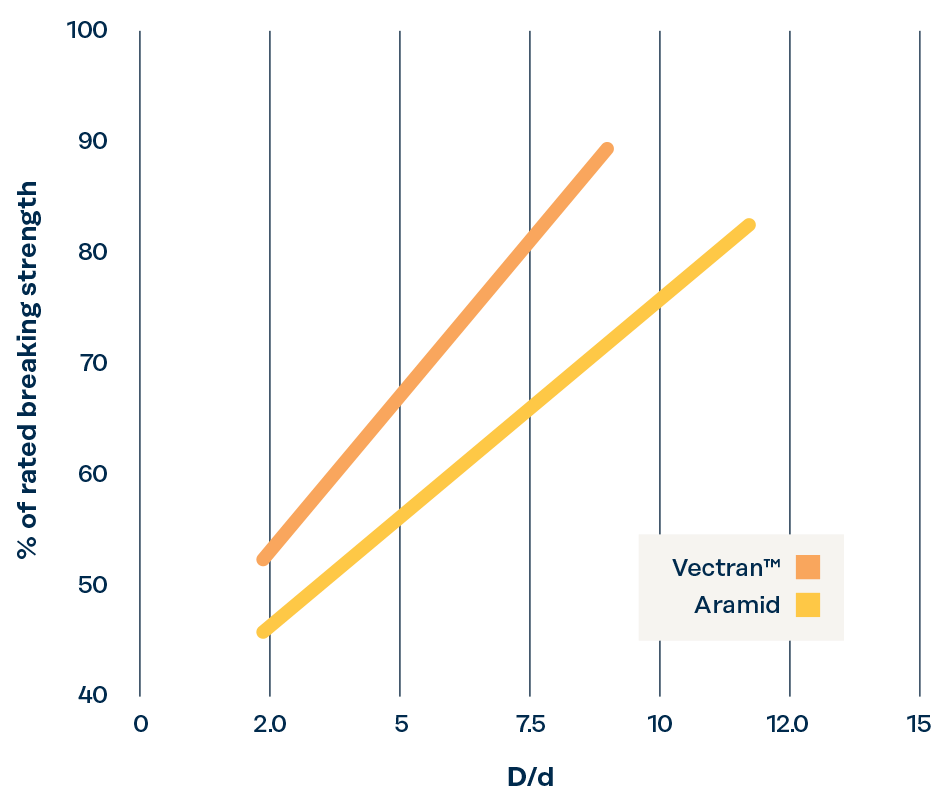

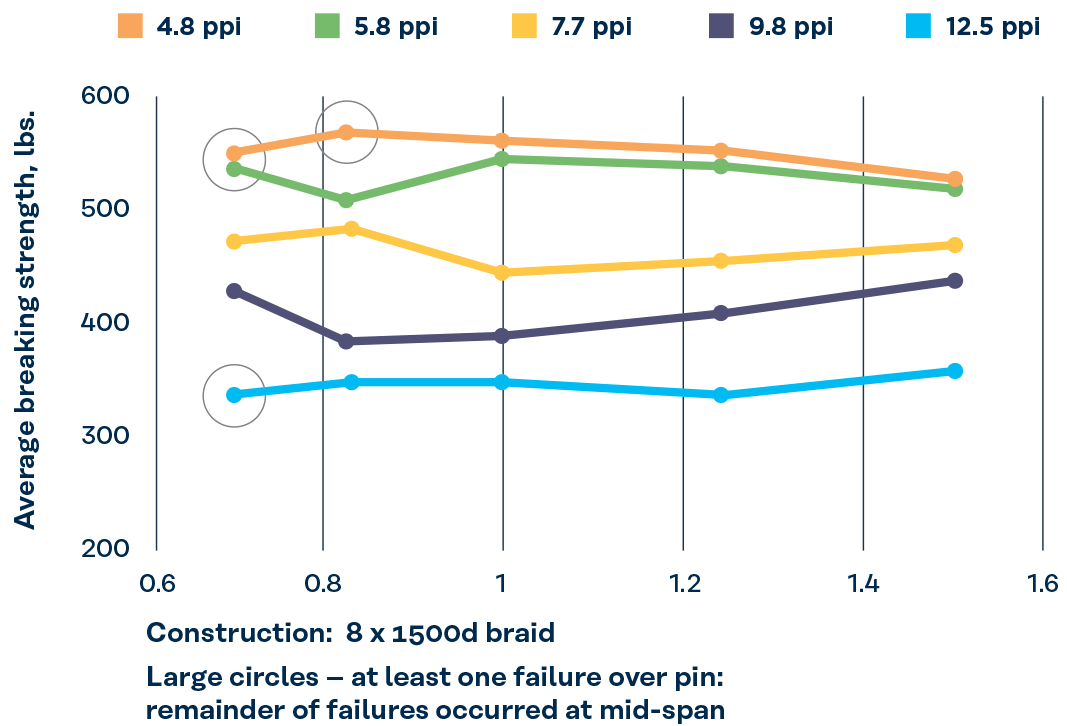

Bend Tolerance

Tolerance to bending around small radii is important in ropes and cables, as it allows the use of smaller running gears or termination hardware. Aerospace and rope manufacturers conducted pin diameter tests on Vectran™ braid and wire rope, respectively.

Breaking strength vs. pin/cord dia. ratio

Breaking strength vs. D:d ratio

Wire rope construction